The railways as drivers of innovation

From railway construction to the system landscape. ÖBB-Infrastruktur provides the stimulus for research and development. We present some examples.

-

Translation of video transcript for reading

ÖBB Infrastructure - Research & Development

Filming, music in the background, text insertsÖBB INFRA

We get the ball rolling

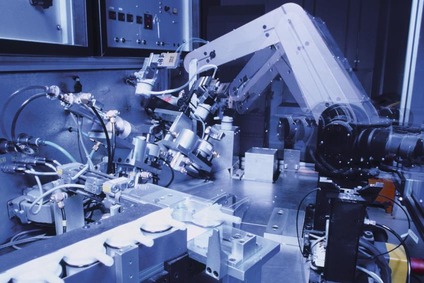

Research & Development at ÖBB-InfrastrukturDifferent research projects of ÖBB-Infrastruktur are presented with short clips.

Free-form surfaces

Cost-effective and rapid erection of a concrete domeLaser scan

Detailed measurement during operationInnoSens

Cameras and sensors record the entire railway infrastructurePantoinspect

Pantograph monitoring to protect infrastructure and vehiclesSafe onLINE

Measurement of overhead line conditionsRailway crossings

Traffic psychology research for more attention at level crossingsClimate change

Acting and reactingFibre optics

Event detection with fibre optic sensorsTrack ecomat

Superstructure protection, water absorption and noise reductionRail head conditioning

Reduce noise emission, minimise wearInnovation test drives

Measuring aerodynamic loads and noise barriersOptimise driving dynamics

Increase comfort, reduce costsTrain running checkpoints

The infrastructure keeps an eye on the vehicles

Translate4Rail - Crossing (language) borders safely and easily

The future of rail freight transport increasingly depends on cross-border cooperation. This is a major challenge, especially in Europe. The railways still have a very national character. Cross-border communication has also proved difficult up to now.

New language tool

That is why Shift2Rail, the railway association UIC and Rail Net Europe (RNE) developed the language tool Translate4Rail. This enables train drivers and dispatchers from different countries to communicate with each other safely, flexibly and effectively across language barriers. Translate4Rail also enables the language level to be lowered from B1.

Translate4Rail will be tested in border traffic between Tarvisio and Villach until September 2021.

Do you want to know how Tanslate4Rail works? Watch the video on Translate4rail.

White Rail Project

Rising temperatures and heat waves cause tracks to become compressed, which makes unrestricted railway operation more difficult. As part of the “White Rail” project, we are changing the colour of the rails to see how this works in a trial run. It is known that darker surfaces absorb temperatures very easily. We hope that changing the colour of the rails to a lighter colour will mean temperatures drop by 5 – 8 degrees Celsius and that there will be fewer restrictions on train traffic due to deformed rails in strong sunshine.

-

Translation of video transcript for reading

White rails

Filming, SpeakerJürgen Neumayr: Today we have the White Rail project here. We are colouring the rail white, on the basis that light-coloured surfaces absorb temperatures less strongly. We have relatively high rail temperatures. Due to the temperature increases, there is always track compression, i.e. the track gives way to tension somewhere. The idea behind this is that we can lower the temperature from the rail somewhat. The rail temperature should go down about five to eight degrees.

My name is Neumayr Jürgen, I am from the ÖBB- Infrastruktur Anlagenservicecenter Bludenz. I travel quite a lot in South Tyrol and Italy and have seen that the rails there are being painted white. I then contacted the Italian state railways and the South Tyrolean Vinschgaubahn and learned from them that they have not had any rail deformations for the last three years because the rails have been painted white. The whole thing started quite simply: The rails were painted with a brush and white paint, then the whole thing was measured and we noticed that there were temperature differences, i.e. lower temperatures of between five and eight degrees. Then they said they would develop a device that could be used in a sensible, environmentally friendly and economical way. We then sat down and made the first design drawings and then put them into practice with the training workshop in Feldkirch. So after two years we have now reached the point where we have got the whole thing on track. We work with an OBW - a superstructure wagon - with a mounted spraying device. We use it to spray the rail, from rail head to rail web to rail foot with white paint, all four sides of the two rails at once. We drive at five to seven kilometres per hour, which has given us the best results so far.

On the first trip we spray the rail head, on the return trip we make sure that we hit the rail foot exactly. This way we paint a large part of the rail web twice, so it gets really nice and rich. The paint is applied, but none of the paint gets into the ballast or the base.

There was a lot of consideration given to the environment when choosing the paint, in terms of spray and environmental impact. It was a challenge to work on this dirty rail without pre-treatment with this white paint. All components, whether it's the pipework, the hoist, the suction point, the processing only works with air. This completely eliminates the possibility of explosive atmospheres at the work site. We can do all the height adjustment with an external fine spindle, from the vehicle. Only the swivel and the tilt still have to be operated manually. The aim would be not to operate these nozzle heads manually from the track, but to use servo motors, set via a control panel, to bring them into exactly the right position so that the paint can really be applied to the rails in the best possible way.

We are now starting in the ASC Bludenz/ASC Landeck area. I would like to measure the temperatures myself throughout the year, which will be recorded with track thermometers. We want to look at the results, and if it works well, it will certainly be rolled out across Austria at some point.